√完了しました! tensile yield strength equation 846836-Tensile yield strength equation

Tensile strength, yield strength, and elongation really do not have such a numerical relationship that can be applied Some people have tried to relate tensile strength to yield strength as a rule of thumb, but these relationships really vary due to processing including heat treatmentTensile strength is usually of a higher numerical value than the yield strength of aThe equation of these two stresses (failure) yields σ = 3 F L 2 b d 2 {\displaystyle \sigma = {\frac {3FL} {2bd^ {2}}}} Typically, L (length of the support span) is much larger than d, so the fraction 3 L 2 d {\displaystyle {\frac {3L} {2d}}} is larger than one

The Differences Between Stiffness And Strength In Metal

Tensile yield strength equation

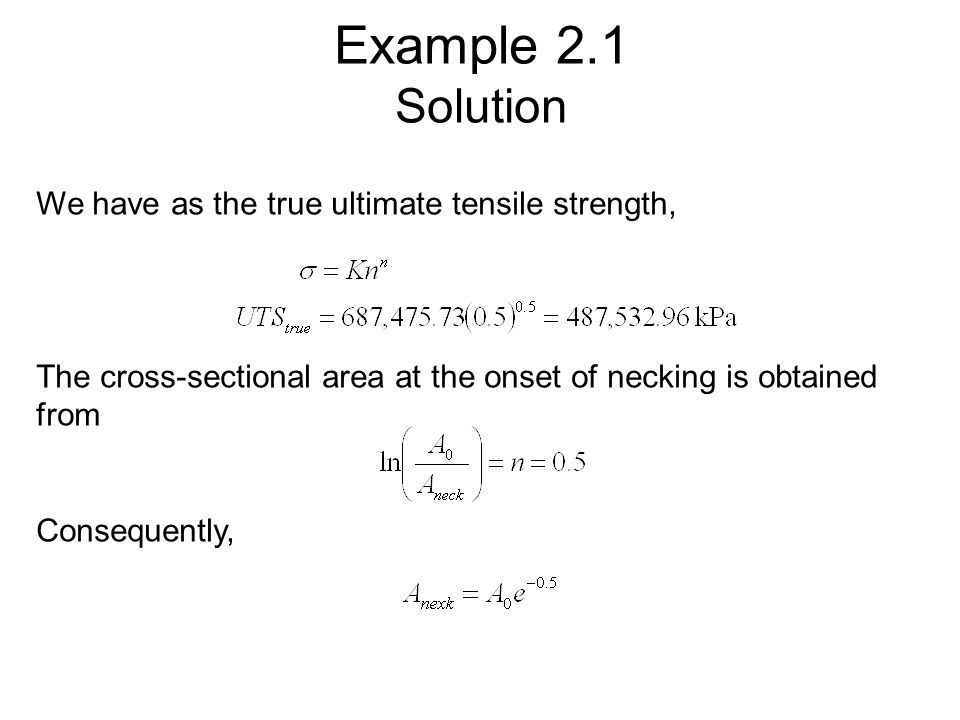

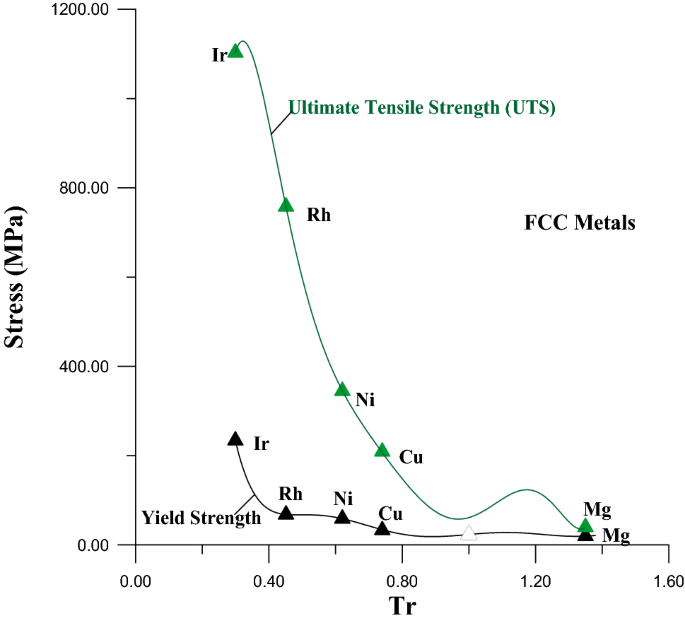

Tensile yield strength equation-The ultimate tensile strength and 02% yield strength of this steel correlated well with hot microhardness data at test temperatures up to 400°C using Cahoon's expressions sigmauts = (H/29)(n/0Using Equation (1813) and approximating the torsional (shear) yield strength as onehalf of the tensile yield strength, the torsional moment is calculated to be 262 Nm 18 A 1cm diameter rod is side pressed from a thickness of 1 cm to a thickness of 095 cm What is the width of contact with the die?

Q Tbn And9gcrf0yb4daxmcs4hece0wbtm Gkjp Dgiun5uwt1stzt02mpf2vo Usqp Cau

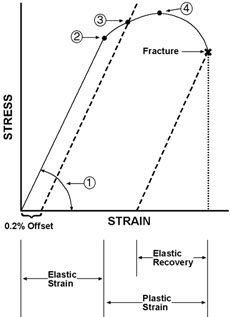

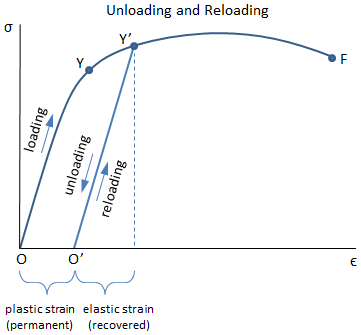

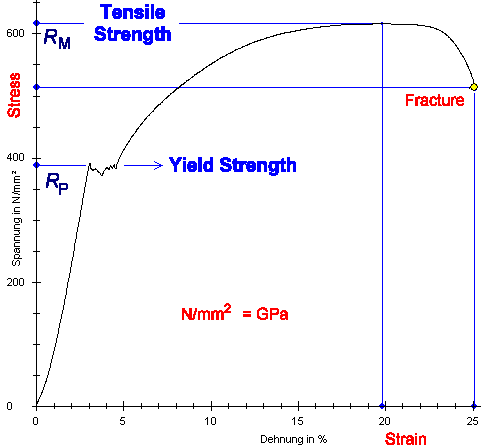

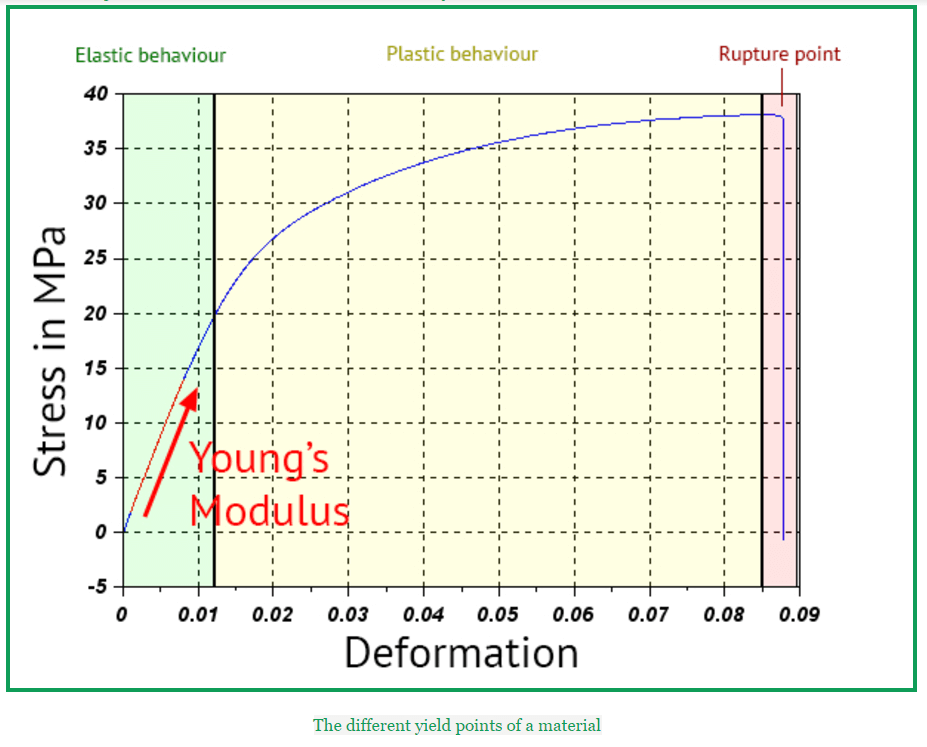

When the elastic limit is exceeded, the curve flattens out as in the stressstrain diagram of the tensile test and indicates the yield force F y With this yield force the induced bending moment M b y = F y ⋅ L S 4 can be determined at the onset of plastic deformation and thus the flexural yield point according to the equation (7)Materials shall adhere asrm yield strength, tensile strength, and elongation of 65 ksi and maximum yieldtotensile strength ratio of 0 in Tension (E) x 10 6 psi in Shear, in terms of E 0 255 117 This is a list of ASTM International standards 097 in 81 99The strength of a material is determined by a tensile test, a test that requires the material to be mercilessly pulled from its two ends The relationship between the stress to which it is subjected and the strain it consequently suffers can be limned by a graph called the stressstrain curve

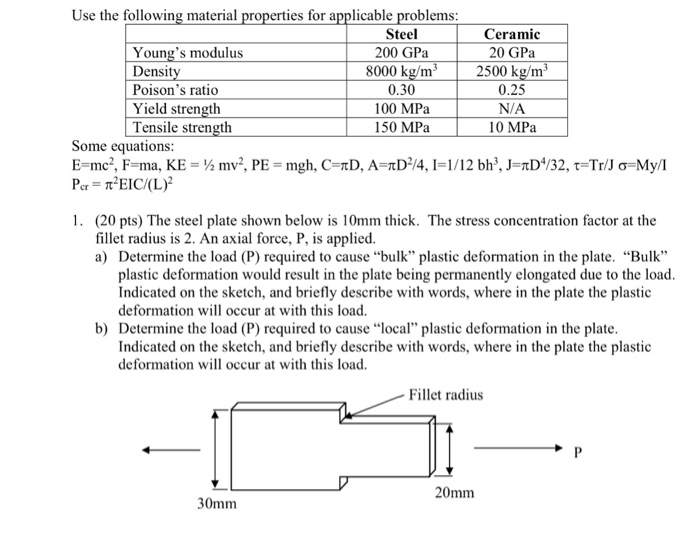

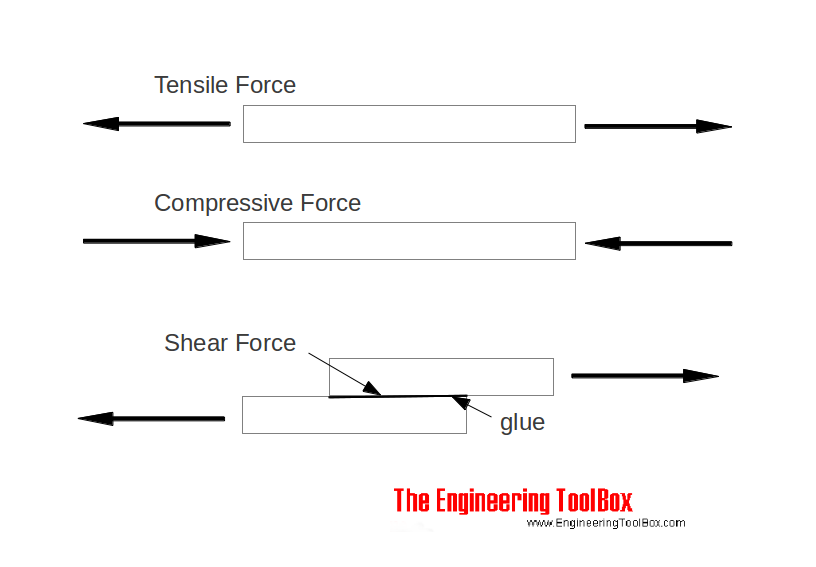

In this case P n is the nominal tensile yielding strength of the member Nominal Tensile Yielding Strength, P n P n is computed using AISC specification equation D21 and is in force units As you will recall from mechanics, for an axial force member, the force in the member equals the normal stress times the cross sectional area of the memberThe allowable stress or allowable strength is the maximum stress (tensile, compressive or bending) that is allowed to be applied on a structural material The allowable stresses are generally defined by building codes, and for steel, and aluminum is a fraction of their yield stress (strength) In the above equation, is the allowable stress, is the yield stress, and is the factor of safety or safety factorWhere σ = stress (N/m2, lb/in2, psi) F = applied force (N, lb) A = stress area of object (m2, in2) tensile stress stress that tends to stretch or lengthen the material acts normal to the stressed area compressible stress stress that tends to compress or shorten the material acts normal to the stressed area

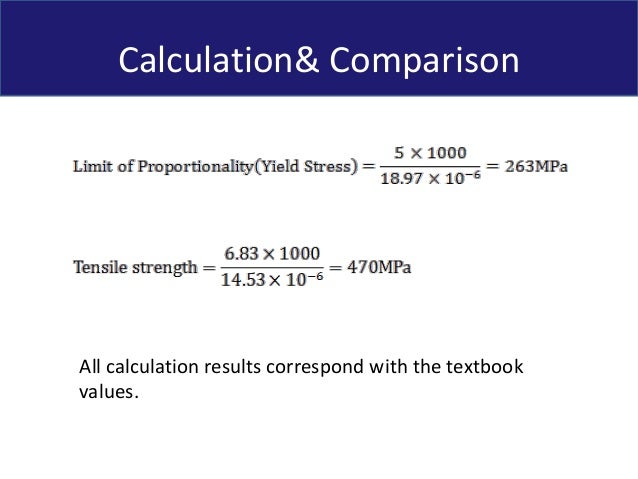

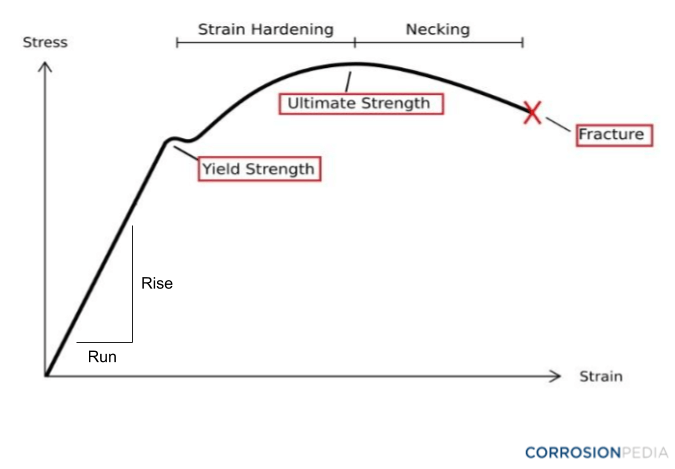

From Table 2, it can be concluded that the tensile strength values are slightly lower than 172 Nm/g for the carboxymethylated pulp (166 Nm/g), and the CMCgrafted has a tensile strength of 150 Nm/g in one investigation (the nanoyield is taken from this investigation), but in a later investigation of the CMCgrafted CNF, the tensile strengthSetup The tensile test is one of the most important testing methods for characterizing or obtaining material parameters In the tensile test, for example, it is determined which load a material can withstand until it begins to deform plastically (yield strength) or under which maximum load the material breaks (tensile strength)The tensile test can also be used to determine the elongation atA is the cross sectional area the force is acting on

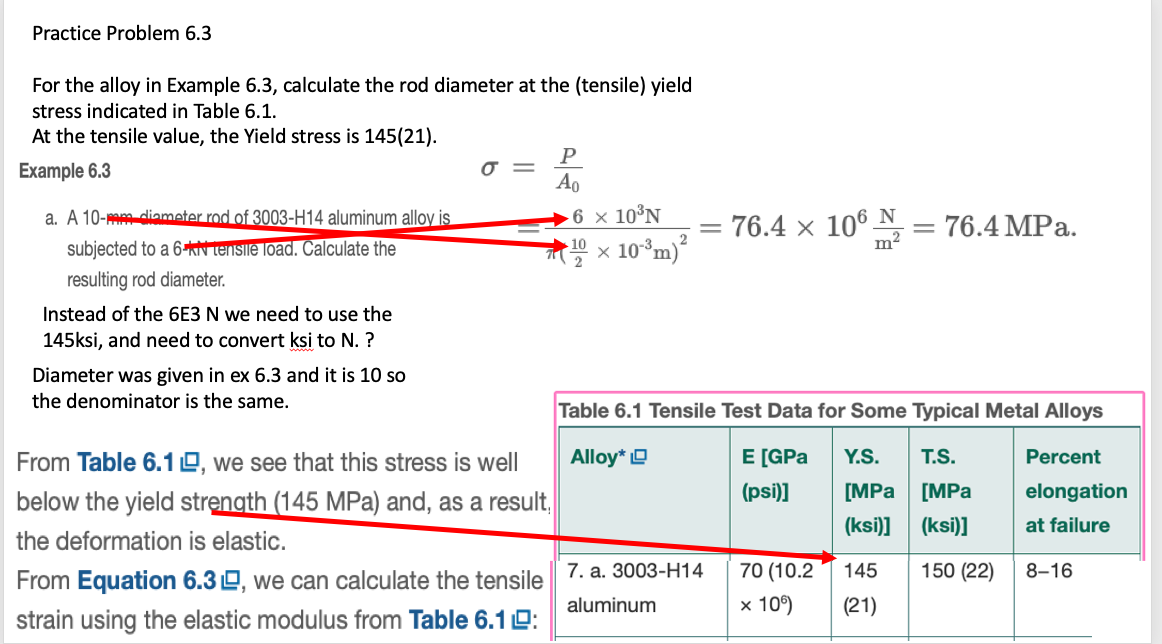

Solved Practice Problem 6 3 For The Alloy In Example 6 3 Chegg Com

Yield Strength Yield Point Stress Strain Curve

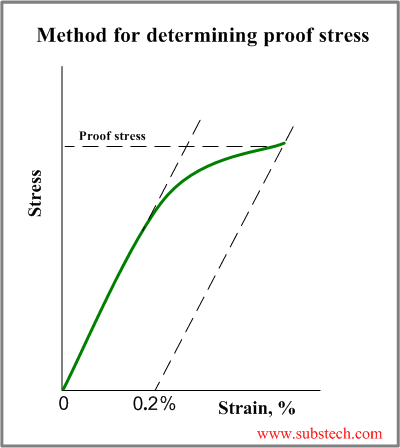

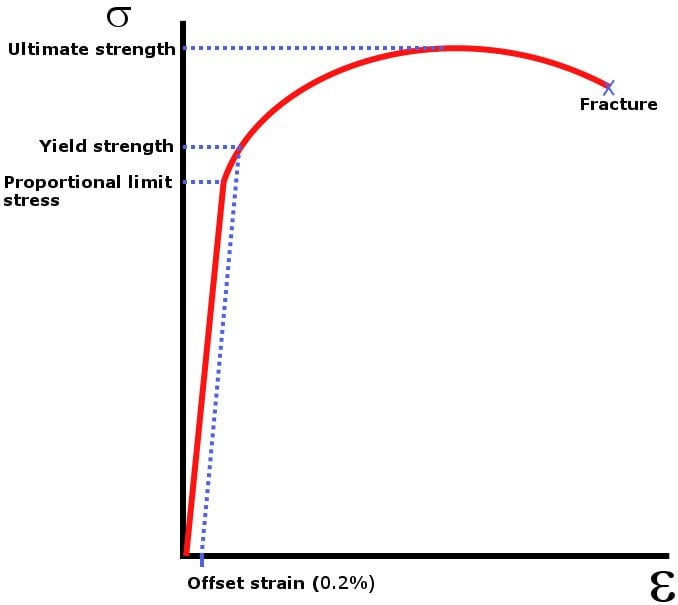

S yield = Minimum yield strength of the bolt grade, ASTM, SAE, etc (psi) s tensile = Ultimate Yield Strength (lbs) t min = Minimum tensile strength of the bolt grade, ASTM, SAE, etc (psi) S sy = Working axial load of fastener bolt (lbs)The yield strength in tension is about 1/3 of the hardness To find the ball park figure for the yield strength convert the hardness number to MPa (or psi ) and divide by 3 For example take the Vickers number, which has the dimension kg/mm2, and multiply by 10 to (approximately) convert it to /mm2 (=MPa) then divide by threeFor materials with no visible yield strengths in the stresscurves, a 02 % flexural offset yield strength \(\sigma_{by02}\) can be defined analog to the 02% offset yield strength of the tensile test This yield point is determined by the bending equation (\ref{biegegleichung}), although, the linear stress distribution is no longer valid and

Engineering Stress Strain Curve

Minimum Yield Strength An Overview Sciencedirect Topics

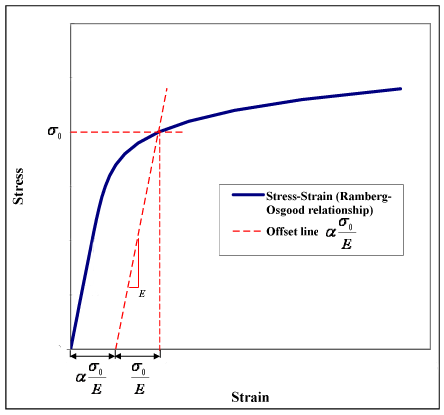

Where S ty is the tensile yield strength, S tu is the tensile ultimate strength, ε y is the strain at yield, ε u is the ultimate strain (total strain at failure), and E is the elastic modulus A better calculation of the modulus of toughness could be made by using the RambergOsgood equation to approximate the stressstrain curve , and thenWhere Y S is the Yield Strength and D S is the Design Stress See our Material Terms and Links page for additional information Related Strength of Materials Area Moment Methods to Calculate Deflection in Beams, Material Specifications and Characteristics Ferrous and NonFerrous, Pinned Columns and Buckling, Moment of Inertia, Section Modulus, Radii of Gyration Equations, Triangular, HexA tensile test is an experimental measure, where you try to elongate an object, while measuring the strength you are using to do so The elongation process is made with a constant speed, until we reach the breaking point This gives us everything we need to draw a force curve based on the elongation

Determining The Flow Stress Curve With Yield And Ultimate Tensile Strengths Part I

What Is The Relation Between Tensile Strength And Young S Modulus Of A Material

The Shear strength of a material under pure shear is usually 1/√3 (0577) times its tensile yield strength in case of Von mises criterion and 05 times its tensile yield strength in case ofS tensile = t min x a Shear Strength of a thread S sy = p r x s yield Where ymin = Minimum Yield of bolt threads engaged (lbs) s yield = Minimum yield strength of the bolt grade, ASTM, SAE, etc (psi) s tensile = Ultimate Yield Strength (lbs) t min = Minimum tensile strength of the bolt grade, ASTM, SAE, etc (psi)What is a tensile test?

Strength Of Materials Basics And Equations

Stress And Strain Mechanical Properties Of Materials

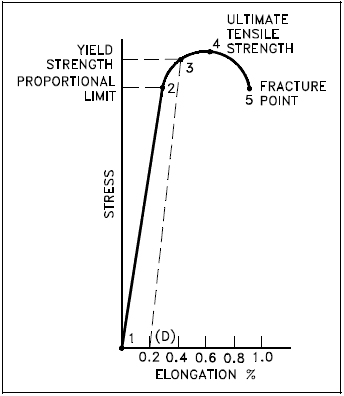

Where S ty is the tensile yield strength, S tu is the tensile ultimate strength, ε y is the strain at yield, ε u is the ultimate strain (total strain at failure), and E is the elastic modulus A better calculation of the modulus of toughness could be made by using the RambergOsgood equation to approximate the stressstrain curve , and then integrating the area under the curveYield Strength Take the minimum yield in psi of the ASTM grade (see our Strength Requirements by Grade Chartfor this value), multiplied by the stress area of the specific diameter (see our Thread Pitch Chart) This formula will give you the ultimate yield strength of that size and grade of boltLimit, yield strength have been used for the first property For the failure stress such terms as ultimate strength, strength, rupture, and limiting stress and many more have been used All of these have had rather different interpretations None have been entirely satisfactory and none universally adopted

Q Tbn And9gcrf0yb4daxmcs4hece0wbtm Gkjp Dgiun5uwt1stzt02mpf2vo Usqp Cau

Spring Minimum Tensile Strength Calculator

What is a tensile test?I typically use 1/2 of tensile to estimate the shear strength However, We can use the 45 degree shear plane theory the relationship to tensile to shear is 1/sqrt (2) which is707 Some sourcesUsing Equation (1813) and approximating the torsional (shear) yield strength as onehalf of the tensile yield strength, the torsional moment is calculated to be 262 Nm 18 A 1cm diameter rod is side pressed from a thickness of 1 cm to a thickness of 095 cm

Tensile Test And Stress Strain Diagram Substech

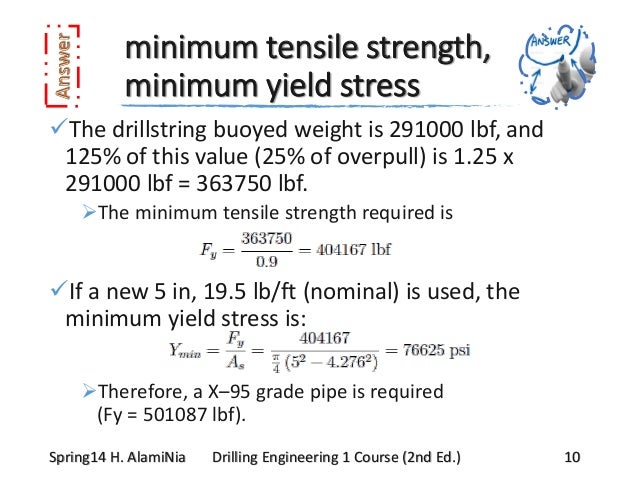

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

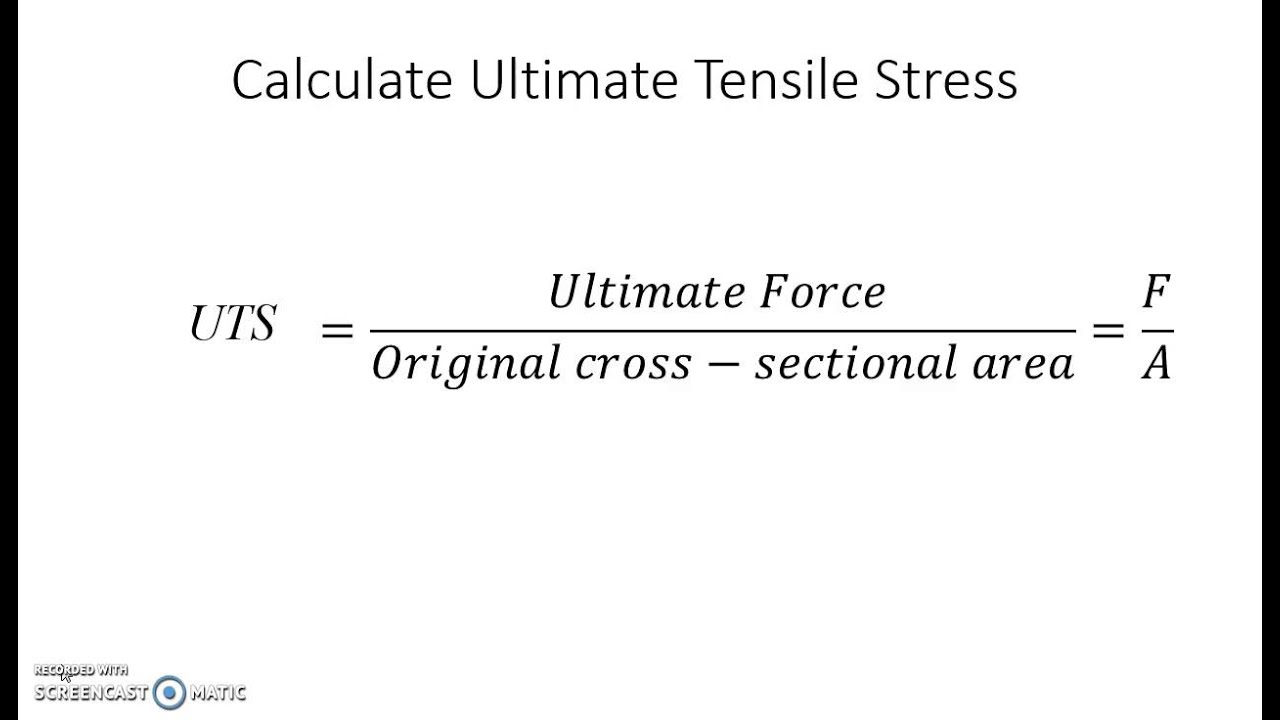

Tensile Strength Formula The following formula is used to calculate a tensile strength TS = UF / A Where TS is the tensile strength;Yield Strength in Tension When the strength of the Bolt in Shear is Given calculator uses Tensile Yield Strength=(2*Shear strength*Factor of safety)/(pi*Core Diameter*Height of Nut ) to calculate the Tensile Yield Strength, The Yield Strength in Tension When the strength of the Bolt in Shear is Given formula is defined as the stress a material can withstand without permanent deformation or aS = Breaking Strength (stress) F = Force that Caused the Failure A = Least Cross sectional Area of the Material Using the above Ultimate tensile strength formula, the UTS can be calculated by dividing the load or force at break and the original minimum crosssectional area

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Q922 De1 L10 V1

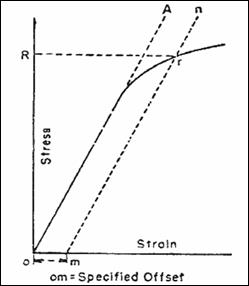

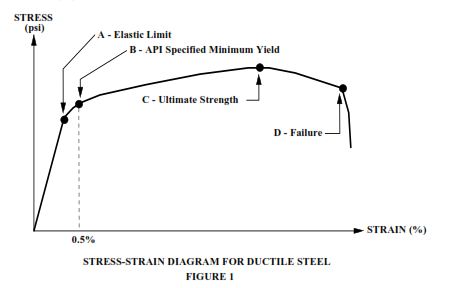

Minimum Yield Strength 80,000 psi Maximum Yield Strength 95,000 psi Minimum Tensile Strength 95,000 psi Hardness Requirement 23 HRC maximum Notes Manufactured to API specification 5CT This is a controlled yield strength material with a hardness testing requirement L80 is usually used in wells with sour (H2S) environments API N80 (or N80When yield strength is reported, the amount of offset used in the determination should be stated For example, "Yield Strength (at 02% offset) = 51,0 psi" Young's Modulus of Common Engineering MaterialsTensile strength then becomes the primary specification parameter in wire with yield and elongation used as reference values Because of the different mechanical properties found in different shapes of copper alloy wire, it is advised to always specify the desired tensile range for wire whether or not a standard temper designation is used

Isbt212 04 3 Stress And Strain Proportional Limit And Yield Strength Youtube

Strength At Break Tensile

Since, Elongation at yield is the deformation of a thermoplastic or thermoset material at this yield point, it is calculated as the relative increase in length Elongation = ɛ = (ΔL/L) x 100 WhereUltimate tensile strength (UTS) is the maximum engineering stress in a tensile test and signifies the end of uniform elongation and the start of localized necking Elastic modulus (E) (also known as Young's modulus) is the slope of the elastic part of an engineering stressstrain curve e 0 is the elongation at YState ν = − ϵ l a t e r a l ϵ a x i a l \nu=\frac {\epsilon_ {lateral}} {\epsilon_ {axial}} Poisson's ratio is sometimes also defined as the ratio of the absolute Absolute Measurement A Measurement made without a direct reference to a second signal or measurement

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Strength At Break Tensile

σ = E × ϵ \sigma = E\times \epsilon σ = E ×ϵ This relationship is only valid in regions where Hooke's Law is valid Hooke's Law states that a restorative force is present in an elastic material that is proportional to the distance the material has been stretchedFrom Table 2, it can be concluded that the tensile strength values are slightly lower than 172 Nm/g for the carboxymethylated pulp (166 Nm/g), and the CMCgrafted has a tensile strength of 150 Nm/g in one investigation (the nanoyield is taken from this investigation), but in a later investigation of the CMCgrafted CNF, the tensile strengthTensile strength then becomes the primary specification parameter in wire with yield and elongation used as reference values Because of the different mechanical properties found in different shapes of copper alloy wire, it is advised to always specify the desired tensile range for wire whether or not a standard temper designation is used

Correlation Between Engineering Stress Strain And True Stress Strain Curve

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

The ductile strain ε is communicated as ε = ΔL/L In the event that a concrete compressive tensile force is applied, the concrete compressive strain is communicated as ε = ΔL/L In view of Hooke's law, the connection among anxiety is communicated as σ = Eε, where σ stress, E Young's modulus and ε strainYield Strength definition, equation and related strength of materials Yield Strength Strength ( Mechanics ) of Materials Strength / Mechanics of Materials A number of terms have been defined for the purpose of identifying the stress at which plastic deformation begins The value most commonly used for this purpose is the yield strengthYield strength (psi) Ultimate (tensile) strength (psi) Total Design Factor Barlow's Wall Thickness Calculator The Barlow's formula calculator can be used to estimate minimum wall thickness of pipe Outside diameter (in, mm) Yield strength (psi, MPa) Internal pressure (psi, mm) Example A53 Seamless and Welded Standard Pipe Bursting Pressure

How To Measure Tensile Strength Elastic Modulus And Ductility Rolled Alloys Inc

Industrial Design Guide Tensile Strength

Young's Modulus or Tensile Modulus alt Modulus of Elasticity and Ultimate Tensile and Yield Strength for steel, glass, wood and other common materials Sponsored Links Tensile Modulus or Young's Modulus alt Modulus of Elasticity is a measure of stiffness of an elastic materialUF is the ultimate force;In real world applications, this equation only gives an approximation and the maximum shear stress would be higher Stress is not often equally distributed across a part so the shear strength would need to be higher to account for the estimate Comparison As a very rough guide relating tensile, yield, and shear strengths

Burst Pressure What It Is And Why It S So Important Corrosion Materials

What Are Tensile Strength Units Quora

A tensile test is an experimental measure, where you try to elongate an object, while measuring the strength you are using to do so The elongation process is made with a constant speed, until we reach the breaking point This gives us everything we need to draw a force curve based on the elongationThere may be situations where yield or proof strength values of steel are known, but ultimate tensile strength (UTS) values have not been reported As the knowledge of UTS is important for quantifying strainhardening properties, an estimation scheme has been developed under the European project SINTAP 1The yield strength in tension is about 1/3 of the hardness To find the ball park figure for the yield strength convert the hardness number to MPa (or psi ) and divide by 3 For example take the Vickers number, which has the dimension kg/mm2, and multiply by 10 to (approximately) convert it to /mm2 (=MPa) then divide by three

Yield And Tensile Strength Engineering Materials Youtube

Mechanical Properties Of Materials Mechanicalc

Yield strength and tension strength of Fe250 is 250MPa and 410MPa respectively, tensile strength is 410MPa whereas maximum compressive strength is only about 35 to 40% of tensile strength Assume tensile strength of Fe250 steel is 410MPa,consider its compressive strength about 35% to 40%,then 30% to 40% of 410MPa = 140MPa to 160MPa, so steelYield Load(Tons) Ultimate load(Tons) Area of Bar, A=∏ D 2 /4 Yield Strength=Yield Load *24/ Area Tensile Strength = Yield Load*24/ Area 1 ½ in 597 928 0196 in2 Psi 65 Psi 2 ½ in 486 765 0196 in2 Psi 46 Psi 3 ½ in 547 811 0196 in2 Psi 12 Psi 4 ½ in 543 13 0196 in2 Psi 10 Psi 5 1/8 in 705 1095

Q Tbn And9gcttwoqta7jtsg 3vilhdf Yhokhwjyvlxmyndyl3ieisjtj3uoc Usqp Cau

Mechanical Properties Ppt Video Online Download

Ultimate Tensile Strength Importance Testing Examples Fractory

Ramberg Osgood Relationship Wikipedia

Http Www Dept Aoe Vt Edu Aborgolt Aoe3054 Manual Expt5 D638 335 Pdf

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

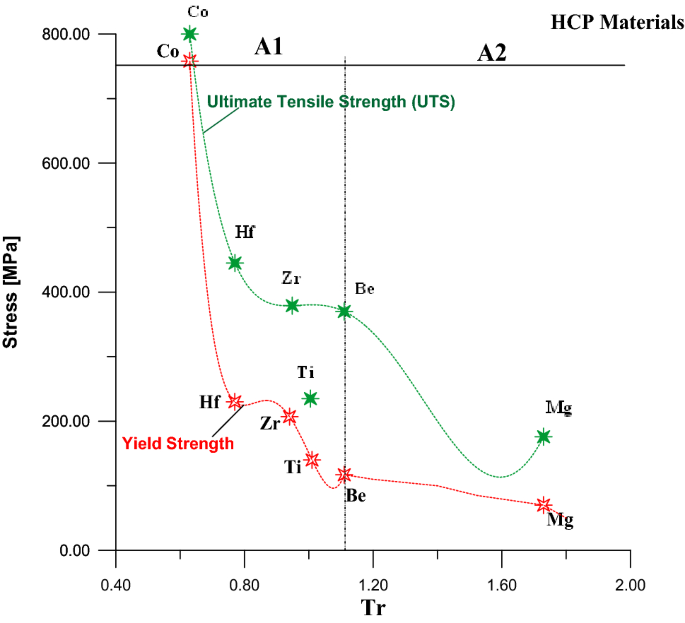

Estimation Of The Ultimate Tensile Strength And Yield Strength For The Pure Metals And Alloys By Using The Acoustic Wave Properties Scientific Reports

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Yield Strength Definition Examples Stress Strain Graph Faqs

Failure Strength Sf From Re Rm R 0 2 E And Efailure

What Is The Difference Between Tensile And Yield Strength Quora

A36 Steel A Tensile Strength Calculation For Reference Not Corroded Download Scientific Diagram

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

Stress Versus Strain

Solved Use The Following Material Ies For Applicable Prob Chegg Com

Estimating Tensile Strength From Yield Or 0 2 Proof Values Twi

Ch 2 Stress Strains And Yield Criterion

Tensile Strain An Overview Sciencedirect Topics

What Is Tensile Testing Instron

Http Www Csun Edu Bavarian Courses Mse 527 Tension Test Mse 527l Pdf

Mechanical Properties Of Materials Mechanicalc

Group Presentation For Tensile Testing

Calculate Yield Stress Youtube

Steel Hardness Vs Yield Or Ultimate Strength Physics Forums

Metal Mechanical Properties Chart Shear Strength Tensile Strength Yield Strength Machinemfg

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

Yield Strength

Yield Strength Strength Mechanics Of Materials Engineers Edge

Importance Of Yield Strength Plastic Deformation To Civil Engineers

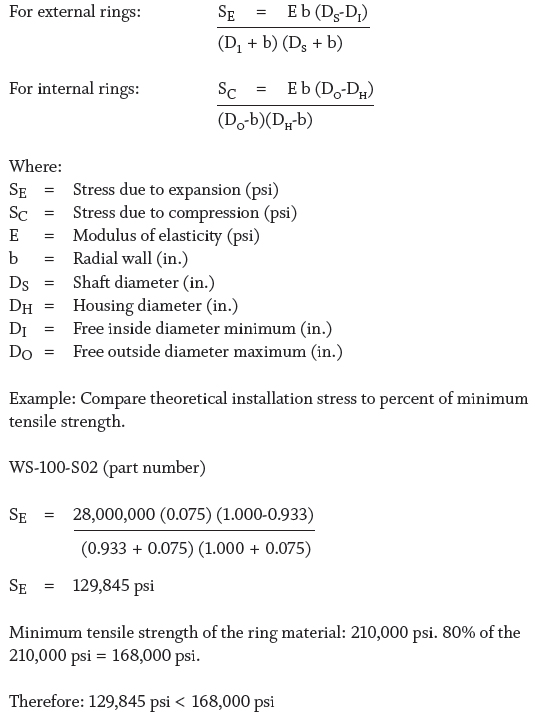

Careful Calculations Affect Ring Design

Q Tbn And9gcq Lokv6u6biweu7e6sd5mb7neolnaw Dcdbogfctf 8hvcdutp Usqp Cau

Stress Strain And Young S Modulus

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

Stress Strain Curve Wikipedia

Science Of Uniaxial Deformation

Http Web Mit Edu Dlizardo Www Uniaxialtestinglabreportv6 Pdf

Yield Strength Strength Mechanics Of Materials Engineers Edge

Yield Strength

Engarc L Offset Yield Method

Why Your Nds Nail Calcs Could Be Wrong And What You Can Do About It Simpson Strong Tie Structural Engineering Blog

Young S Modulus And Tensile Strength All You Need To Know

What Is A Tensile Modulus Definition From Corrosionpedia

Modulus Of Elasticity Instron

How To Find Yield Strength Quora

The Differences Between Stiffness And Strength In Metal

Properties Of Metals Engineering Library

Solved Problem 1 Find The Ultimate Tensile Strength An Chegg Com

Effect Of Yield Strength On Wear Rates Of Railway Wheels

Yield Strength Of Plastics Basic Principles The Tensile Test And Material Property Table Engineeringclicks

Yield Strength Modulus Of Elasticity Tensile Strength Formulas

Cee 3710 Strength Versus Stiffness

Cold Working Is Actually Strain Hardening Basic Equation Relating Flow Stress Strain Hardening To Structure Is O I Gb 1 2 Yield Stress Increases Ppt Download

Estimation Of The Ultimate Tensile Strength And Yield Strength For The Pure Metals And Alloys By Using The Acoustic Wave Properties Scientific Reports

Yield Engineering Wikipedia

What Is The Formula For Tensile Strength How Is This Determined Quora

Thread Yield And Tensile Strength Equation And Calculator Engineers Edge Www Engineersedge Com

Allowable Stress In Asme Viii 1 3 Api 650 Api 653 Amarine

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

Tensile Testing Polymer Processing And Testing

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

Mechanical Properties Of Materials Mechanicalc

Engineering Stress Strain Curve Part One Total Materia Article

Web Adanabtu Edu Tr Files Iyilmaz Duyuru Dosya Me 7 E2 80 93 chapter 3 P3 Pdf

Efatigue Glossary Ultimate Strength

Effect Of Yield Strength On Wear Rates Of Railway Wheels

Strength Of Materials Dt Online

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Www Usna Edu Naoe Files Documents Courses En380 Course Notes Ch10 Deformation Pdf

Ultimate Tensile Strength Uts Stress Strain Curve

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

Finding 0 2 Offset Strain Dplot

Mechanical Testing Tensile Testing Part 1 Twi

Casing Design Theory And Practice Material Properties Definition Drilling Manual

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

What Is Ultimate Tensile Strength Science Abc

コメント

コメントを投稿